H-UV

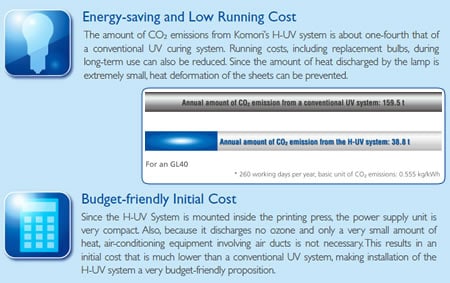

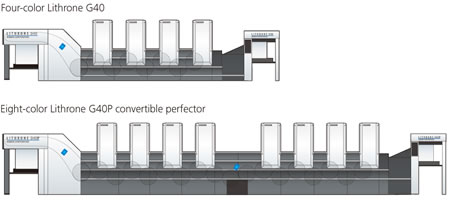

The Komori H-UV System is an innovative UV curing system that uses a UV lamp developed with Komori know-how and high-sensitivity UV ink. With just one lamp mounted in the delivery, this system offers high print quality and reliability as well as excellent economic and eco-friendly performance.

Shorter Total Turnaround Time

Job turnaround time is dramatically shorter than with conventional printing because printed items are cured instantly by an in-line process. UV curing is extremely effective in shortening the time from receipt of materials to delivery because finishing work such as cutting, die cutting and folding can be performed immediately.

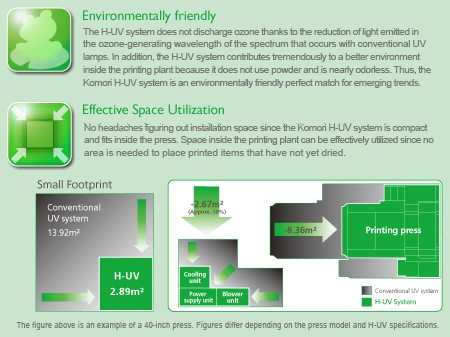

Reduction of Stock Space

Since there is no waiting for printed items to dry as required with conventional printing, a large stock space for printed work is not required. The stock space necessary to accommodate the increasing number of short runs of varied items can be reduced.

Improved Quality due to Powderless Operation

Since the entire printing process is powderless, the plant has none of the troubles associated with the scattering of powder granules. The surface of printed items is smooth, which makes surface processing in postpress very easy. Also, since the problems resulting from supplementary printing by an on-demand press can be reduced, UV curing can facilitate more orders in applications that require no adhesion of drying powder. The elimination of the dry down phenomenon also makes it easier to check quality.

More info Inquiry