Varnishes

Fast drying emulsion with a satin finish. The coated material has good water resistance suited to double sided coating applications and work requiring subsequent UV varnishing.

Fast drying emulsion with a matt finish. The excellent coated material has good water resistance suited to double-sided coating applications and work requiring subsequent UV varnishing or lamination. The dispersion varnishes have ISEGA Certificate (for use in direct contact with food).

W6000 is a gloss coating for single and double side applications. It can be used for carton packaging food, non-food and work & turn jobs. The coated material has good water resistance and is suitable for work requiring subsequent UV varnishing. Tests should be conducted with the specific UV lacquer to be used. The dispersion varnishes are ISEGA Certificate (for use in direct contact with food).

ADDITIONAL

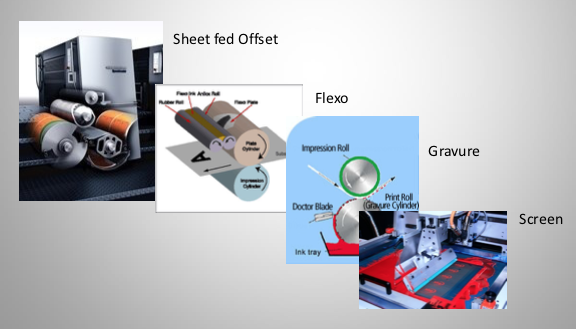

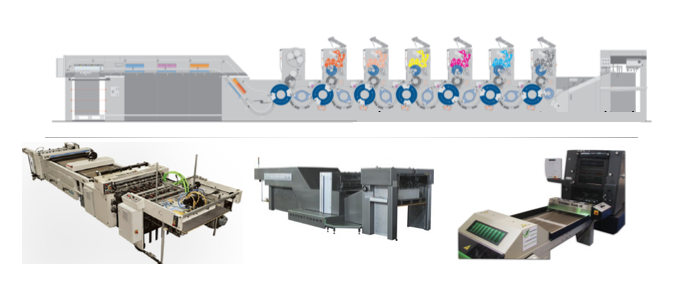

Main kinds of coating

- High Gloss & Gloss Coatings

- Neutral or Satin Coatings

- Matt & Extra Matt finish Coatings

- Single & double sided Coatings

Application Methods

End Uses

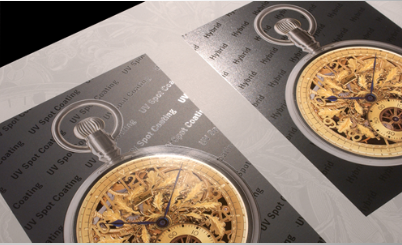

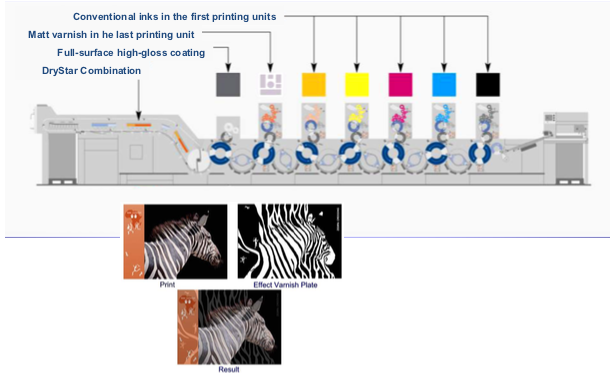

Drip - Off

Quality Control (Production Control)

To guarantee quality and depending on coating type, the following production quality control tests are perfomed.

- Viscosity

- Gloss values

- Drying speed

- Visual evaluations

- Solid tests

- Dispersion control

- (Wet) Block resistance test

- Hot foil stamp test Slip test

- Heat resistance test