AUTOMATIC THREAD BOOK SEWING MACHINE FF-280 4D

The Smyth FF-280 4D is the top-of-the-range sewing machine for the very highest quality in Smyth-sewn book production.

FEATURES:

- Patented Smyth 4D feeder - Guarantees care and reliability as well as handling all paper and signature types

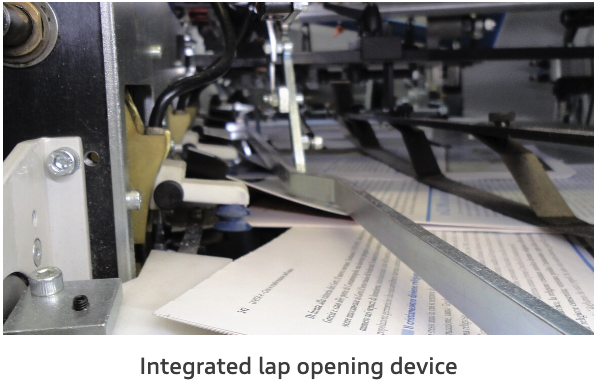

- Integrated lap opening device - Facilitates opening signatures with lap (even with variable lap size)

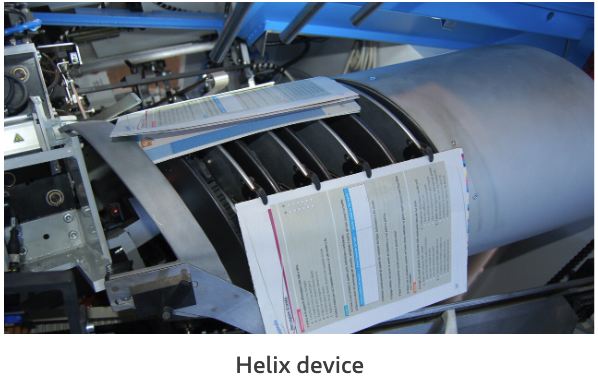

- Helix device - Ensures the signature is opened correctly on the fixed saddle, regardless of the signature type

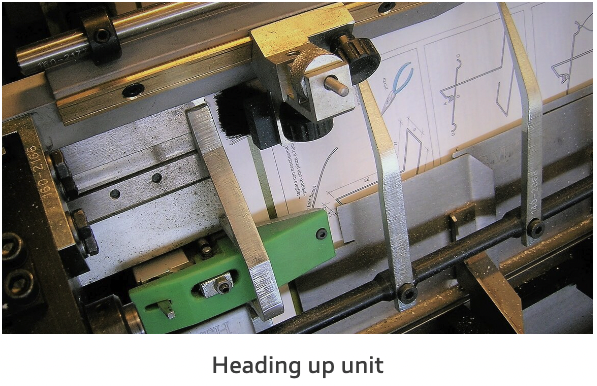

- Mixed vacuum and pressure heading up system - For the perfect head alignment of inserted signatures on the mobile saddle

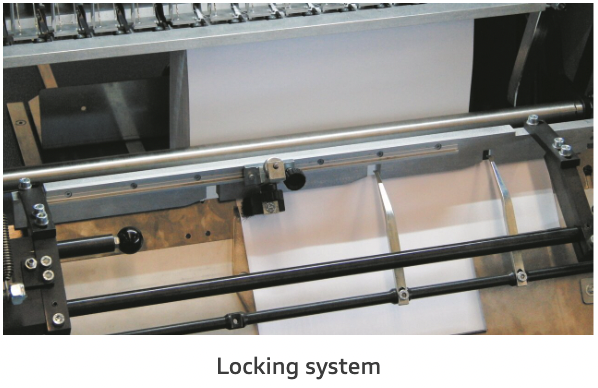

- Signature locking system - To ensure stitches are perfectly centered on the spine of the signature

- Compact sewn book - With any type of paper or signature

Patented Smyth 4D feeder

- Signatures are transported in a shingled stream by means of a geared belt.

- The suction cups carry out a combined movement: Moving forward in the same direction and at the same speed as the signatures to increase their contact time with the paper. Transportation speed gently opens the signature edge.

- Signatures are positioned at an angle to their direction of travel.

DETAILS:

- Integrated lap opening device - In addition to the 4+4 openings managed by the suction cups, the machine can also process signatures with a lap facing the same side or in "come and go" mode. The process is managed electronically, which allows even signatures with an uneven lap or shorter inserts to be opened smoothly and easily.

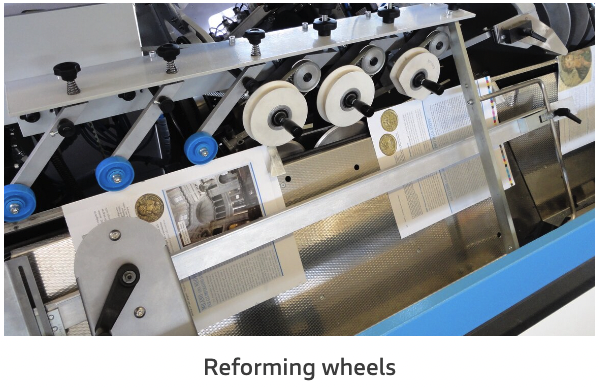

- Reforming wheels - The three wheels that comprise the signature spine reforming system ensure that the back is completely opened, the signatures centered precisely on the mobile saddle, and the sewing stitches perfectly aligned.

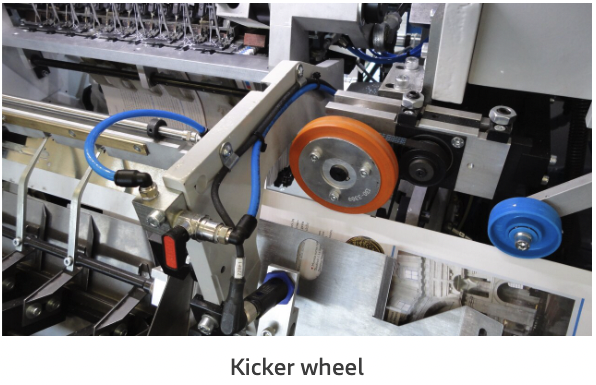

- Kicker wheel - The kicker wheel automatically manages system speed according to signature weight and thickness. In the event of particularly lightweight paper, the acceleration speed of each individual signature on the saddle can be programmed and managed.

- Locking system - The mobile saddle is equipped with a signature locking system. This system holds the signatures in position at the top of the saddle and assures the exact centering of the stitches on the spine.

- Heading up unit - A vacuum and pressure system facilitates heading up on the inserted signature head side. When there are no inserted signatures, the vacuum is turned off and the heading-up unit works with the pressure system.

- Operator interface - A 12" touch screen located on a pivoting arm allows the operator to manage operations from both sides of the sewing machine. Programming and diagnostics are carried out by OMRON PLC.

- In-line connection - The standard sewing machine is supplied ready for a future in-line connection to a Smyth P12 series gathering line. The modular design of the UNIT and CONCEPT gathering and sewing lines allows all Smyth automatic sewing machines to be purchased individually and later integrated into the line.

- Helix device - Designed to allow any type of signature or paper to be loaded onto the fixed sewing machine saddle from the feeder smoothly and reliably while controlling operations to ensure the signature is kept open.

- Automatic safety guards - Automatic safety guards complete with a range of safety features are ergonomically and functionally designed to provide operators with clear visibility of the entire production process and easy access to the thread stitching plate. A perfect combination of design and functionality.

OPTIONAL:

- Signature sequence control - Precision signature sequence control is carried out by a high-speed OMRON camera by reading barcodes, text, or images and selectively filtering out any discrepancies.

- Easy Stack stacker - The Easy Stack facilitates operator unloading operations by stacking the sewn books. The book stack, with non-alternating backs, can be programmed up to a height of 120 mm.

- Pasting device - In order to give the book spine greater robustness, a pneumatic gun applies a thin strip of vinyl glue near the spine of the signature

TECHNICAL SPECIFICATION

PARAMETER

VALUE

Max mechanical speed:

180 cycles/min

Signature size:

Max. 420 (head to tail) x 320 (back to front) mm | Min. 135 (head to tail) x 80 (back to front) mm

Openings:

4 upper + 4 lower + integrated LAP opening device

Number of stitches:

9

Length of stitches:

24 mm

Compressed air consumption:

300 Nl/min at 6 bar

Voltage:

400V - 50Hz - Three-phase

Size:

3,10 x 2,00 x h 1,65 m