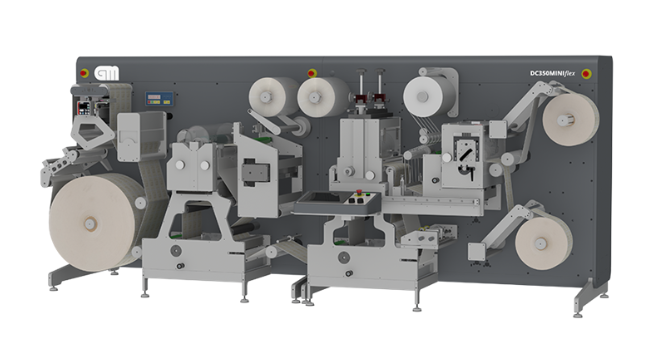

DC350Flex Fast finisher

DC350Flex - Compact Integrated Converting Line for Labels

- Maximum modularity

- GM SmartFlexo semi-rotary with spot

- GM SmartSlit - automatic slitting station

- GM SmartStrip - high speed stripping

- Online support and remote diagnostics

- Industry 4.0 ready

- Also available in 550 mm web width version

CHARACTERISTICS

The DC350Flex - a new, efficient and economical label finisher build in volume at GM with the same components as the DC350 Modular Premium Finishing Line.

The Flex has handy options like format free semi-rotation spot varnish, die-cutting, slitting and dual rewind.

Upgrade with value options like Turret rewinding, in register lamination (multi-layer), SmartSlit or SmartCrush, SmartStrip, Corona, web clean, back scoring & inline buffer.

The new DC350Flex is prepared for in-line operation with all major digital presses providing professional label printers with a complete and versatile solution for high volume digital printing.

FEATURES

- Easy to use

- Automated production with job recall and QR code option

- Modern platform ensuring quick setup and flexibility

- Industry-leading user interface giving the operator a graphical representation of the machine as installed

- Industry 4.0 compliant

- "Never break" technology prevents matrix rewind break

- Web-advance for a fast roll change

- Online Support – easy web access and maintenance

OPTIONS

GM SmartFlexo Station - flower style with optional semi-rotation in flexo unit for format free print (only one cliche cylinder) and with registration system (spot varnish / cold foil print).

GM SmartStrip - ensures trouble-free operation even while converting delicate substrates and complex label shapes at high speed.

GM SmartSlit - automatically positions up to 16 knives in 2 minutes, saving valuable time on short-run jobs.

GM SmartCrush - an ultra-quick set knives system, allowing fast and precise setting of each crush knife – also while running.

GM SmartLam - multi-layer labels are often used for pharmaceutical and medical label applications – especially when government regulations require product information to remain intact with the product.

GM Semi-Automatic Turret - it offers very quick make-ready times, unlike conventional rewinding. This allows shorter runs to be produced both quickly and more efficiently.

Watch the same family machine here.