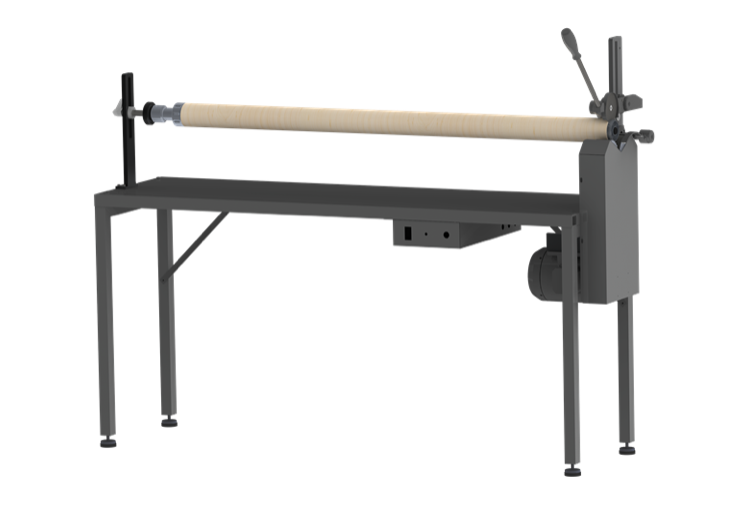

P160LC MANUAL CORE CUTTER

The P160LC is a manual entry-level core cutter, designed to easily cut the cores in a simple and efficient manner. This inexpensive machine is the perfect complement to our smaller converters like DC350NANO and DC330MINI. GM put in 43 years of converting experience into developing the P160LC. This means optimal service-friendliness and high production speed in core cutting.

CHARACTERISTICS:

The P160LC is an entry-level model designed with a low price in mind. Despite its low price, it is still compatible with the tools on the bigger PNT/PNTS models. This means that adapters can be reused in case of an upgrade. The cutting on the P160LC is done using a steel disc knife against a nylon anvil. This prolongs the knife's life while retaining a good cutting quality. A ruler on the end stop makes it easy for the operator to adjust the cut length.

FEATURES:

- Precise cut and smooth core edges

- Repetitive and accurate cutting process

- Build-in ruler makes cutting length adjustment quick and easy

- Easy setting of cutting depth

- End-stop and nylon anvil extends the lifetime of knives

- Quick and easy exchange of cores with different diameters

- Simple, robust design ensures easy operation and a long lifetime of the machine

- Nylon anvil extending the life of the knife

- Basic machine includes one 3” / 76 mm adapter and an anvil

- Integrated two-handed safety system keeps the operator's hands away from the knife

- Cutting of cores with a diameter from 12.7 up to 153 mm and a wall thickness of up to 15 mm