Densitometers

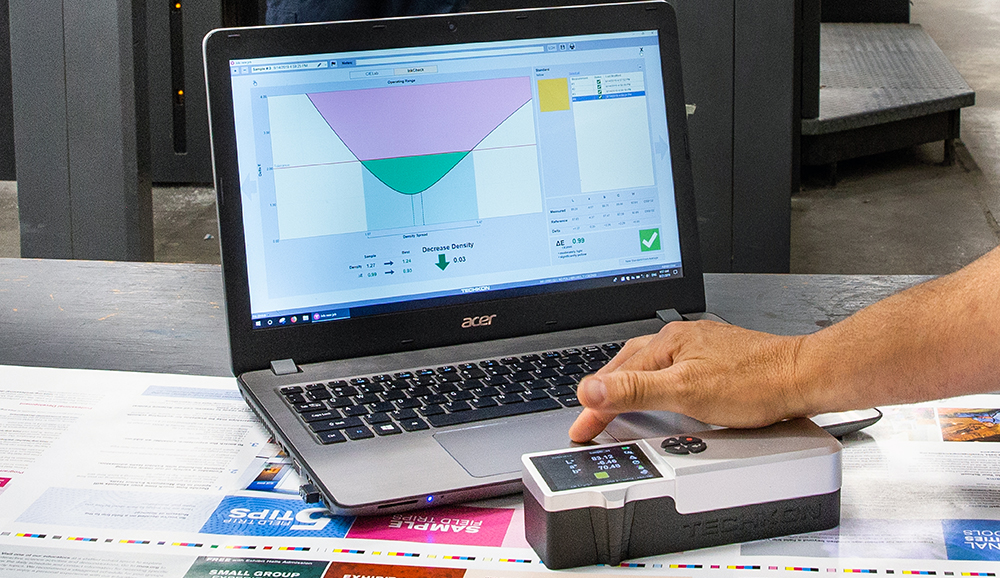

ChromaQA Client software

GIVE CLIENTS THE EXACT COLOR THEY EXPECT

ChromaQA is a powerful color quality solution that enables a more predictable and repeatable print manufacturing process to ensure your presses are delivering perfect results every time. You’ll reduce the number of re-makes and recognize a significant savings in ink and paper by detecting color problems early.

Video Inquiry5 EASY STEPS TO REPEATABLE SUCCESS AND HAPPIER CUSTOMERS

1. Enter the job information, including client’s color specifications and all print tolerances

2. Retrieve the job, on press, start taking measurements, and let ChromaQA automatically show you how to achieve the target values.

3. Continue to spot check color quality throughout press run, using instant pass/fail feedback to maintain perfect quality.

4. Use automated reports to show your customer they’re getting exactly what they specified.

5. Enjoy the feeling of success as repeat business rolls in.

A TOTAL PRINT COLOR QUALITY SOLUTION

ChromaQA connects all members of a printing team. The Ink Kitchen can define & manage color assets, Prepress can create & set job specifications, the Pressroom can measure color bars from live jobs & view pass/fail, and the QA Department can design internal & customer reports.

ChromaQA is flexible enough to benefit any size of print operation, from a smaller printer with a single press to large enterprises with multiple printing locations.

ChromaLT

GET UP TO COLOR FASTER

Designed for small and mid-sized packaging printers who are looking for an affordable solution that is easy to deploy in the pressroom, ChromaLT is the ultimate companion software for your press-side spectrophotometer that makes matching color on press quick and easy. ChromaLT will guide your operators on how to get a match with either specific ink density adjustments or by toning the ink when density adjustments cannot get you there. Give your operators color matching feedback that is easy to understand, actionable, and with clear Pass/Fail indications. When the job is done, the measurements are saved and a report can be generated for the quality department or the end customer to show that colors were printed in tolerances and the job was a success. In the end, ChromaLT will improve your print process efficiencies by removing the color matching guesswork, cutting your make-ready times, and ultimately increasing your profitability.

Video Inquiry

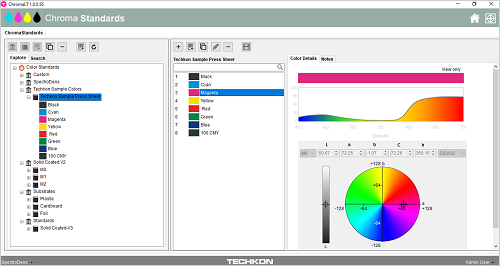

STORE, ORGANIZE & SEARCH YOUR COLOR STANDARDS

- Centralize the storage of your color standards by organizing into Books and Libraries

- Add new colors via measurement, import from file, or text entry

- Search for colors by name or by deltaE threshold

- Rationalize or “clean” your color standards database with the Search by deltaE feature to find duplicates and similiar colors

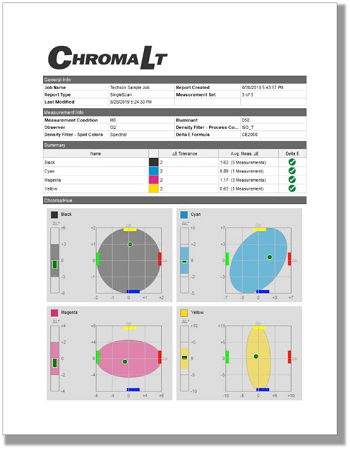

STORE & REPORT ON YOUR PRODUCTION DATA

- Create customized job reports with either your logo or your customers logo

- Automatically filter out “make-ready” measurements from reports

- Report on a single measured sample or the average of multiple samples

- Plot trend graphs to show the quality throughout a press run

- Provide detailed job reports to the brand owner or customer

- Maintain a history for how an item or colors print over time

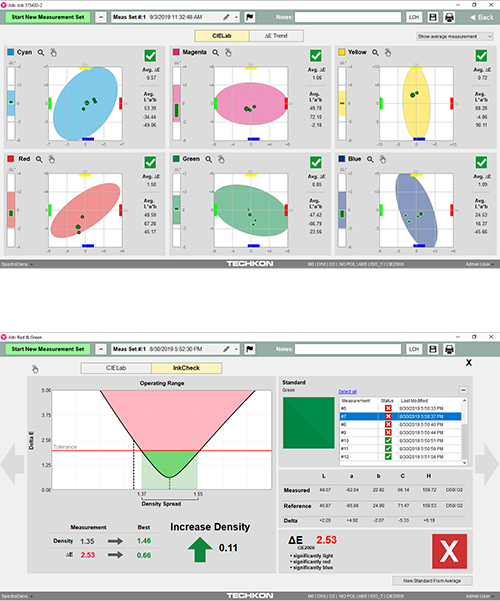

SIMPLIFY SPOT COLOR MATCHING IN THE PRESSROOM

- Pick the colors, set the deltaE tolerance for each, and either Save or Run the job immediately

- Choose up to 8 colors per job and set the deltaE tolerances for each

- Measure colors in any order and ChromaLT automatically identifies the correct color standard in the job

- See instant PASS/FAIL and color difference results with easy to understand graphics

- Get actionable feedback with InkCheck technology which provides specific density adjustments to achieve lowest possible deltaE on press

- Check to see if your ink needs to be remixed

- Once in production, periodically check colors and monitor trend charts

- Create reports for internal and external stake-holders

- Reduce trial-and-error with actionable feedback and clear direction for operators