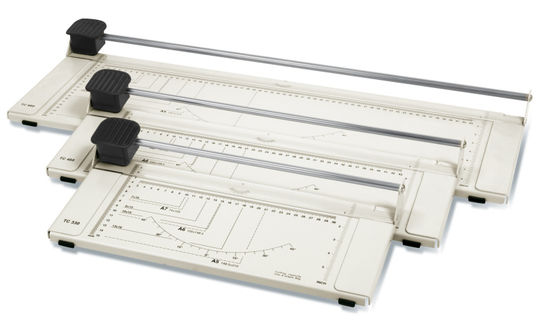

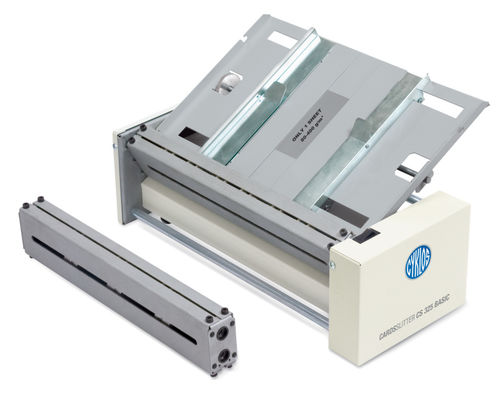

Card Cutting Equipment

Cyklos is traditional Czech company with 90 years of experience. At present, company offers wide range of creasing, perforation, folding, cutting and punching machines.

Systematically Cyklos does its best to improve manufacturing processes so they can meet ISO 9001 quality standards. Cyklos is proud to say that they have been ISO-certified company for more than a decade now.

Caslon®Limited extensive range of Card Finishing Equipment has evolved into one of the most completed in the world.

Caslon®Limited extensive range of Card Finishing Equipment has evolved into one of the most completed in the world.

Do you want to cut business cards?

We have a model to suit your requirements and budget: