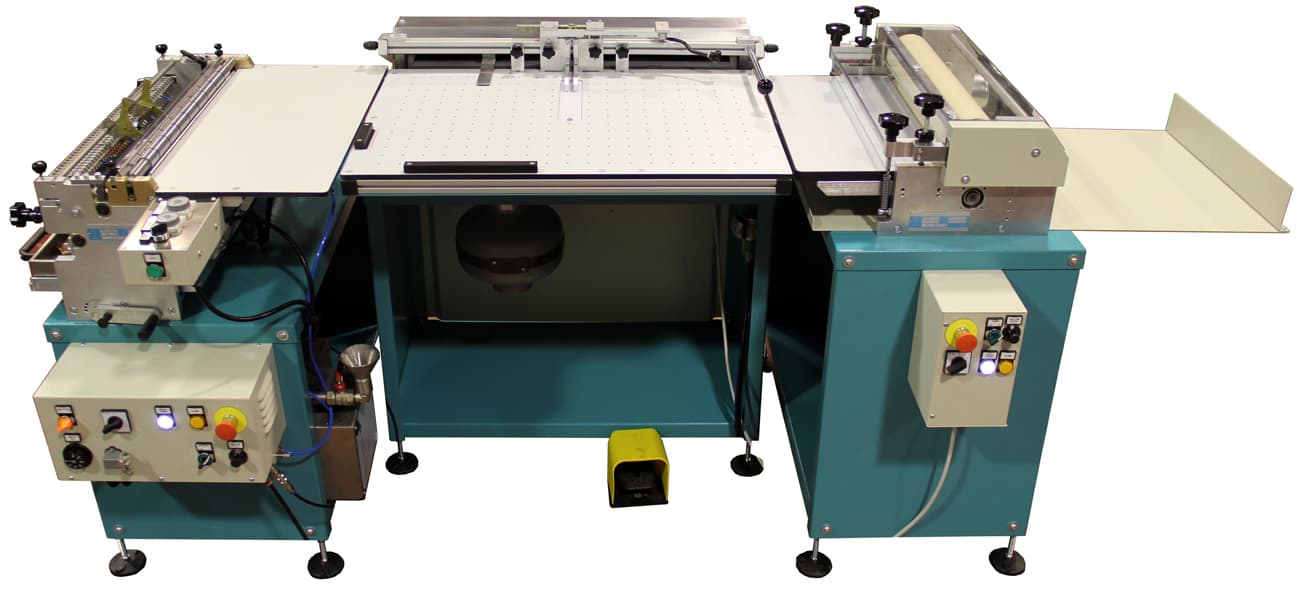

Q-COVER ONE

Case making machine, which applies glue on the cover, turns-in one side at a time and folds the corners automatically. The cover is then passed into the nip-roller, output on collector table.

Technical specification:

- Min. size, cm: 10 x 10

- Max. size, cm: 48 x 70**

Available options:

** 48 x 110 cm and 70 x 110 cm

Available Options for Q-COVER ONE - How to choose the right ones?

- It depends on what the customer needs:

- K-BOX- Kit for positioning boxes - is.. well, useless, if you don’t need to do boxes.

- K-5B- Kit for positioning up to 5 boards. The same goes for the kit for 5 boards (say you need 3 only, 5 would be overkill). Some customers want an extra set of guides to allow more boards to be placed on their sheets. We usually offer the 5-board kit anyway, and it’s up to the customer to decide if he will need it or not. I’m no expert, but an example of a product with 5 boards could be a catalog box, that closes its spine on top of another spine (may it be with a magnet or else). In that case, you would have a short board (initial spine), then a central board, then the middle short board (central spine), then another board, then the closure spine.

- Q-GLUE- Separate glue tank heater with re-circulating pump and H-VISC Viscometer - on the other hand, is the only option that affects your working environment and productivity. As you already know, the Q-GLUE is a glue tank with a viscometer, that allows for automatic management of the viscosity of the glue: it will add water (or let it evaporate) when needed, allowing for the glue’s viscosity to be regulated based on the settings the customer wants/needs. It also mixes the glue inside the tank autonomously. Why is it important to have a Q-GLUE? It will save a significant amount of time, compared to adding and melting glue (the Q-GLUE holds 25kg of glue), water, and regulating the viscosity manually. You set the Q-GLUE once, and only need to add glue once in a while (8-10 hours depending on the rate of glue consumption and format of the material used), and clean it at the end of the day (literally takes less than 5 minutes and requires no detachments whatsoever if performed correctly). Q-GLUE saves time and increases productivity by handling the glue’s viscosity automatically. The machine Q-COVER can work as a standalone unit (without Q-GLUE) by the standard. Q-GLUE has a much bigger glue tank - 25 kg compared to the LYNX standard of 4 kg - and mixes it automatically. The customer will need the viscometer the moment they feel like they can’t handle the viscosity of glue themselves, but want either something or someone else to deal with it for them. Regulating the viscosity of glue is extremely important, and doing it manually can result in less performance (time lost adding water and mixing glue), or simply errors in the production (glue is too slimy and doesn’t stick correctly, or is too dense and sheets get stuck, etc.).

- AURVARINV (x2)- Speed variator for Q-COVER ONE models (On Gluer & Nip Roller). The Q-COVER ONE (standard) works with a single speed. The speed variator allows the customer to work faster or slower based on his pace and the kind of material that is being used. The base model of a Q-COVER TWO allows for regulating the speed without the need for an optional variator (because the variator is already included).